-

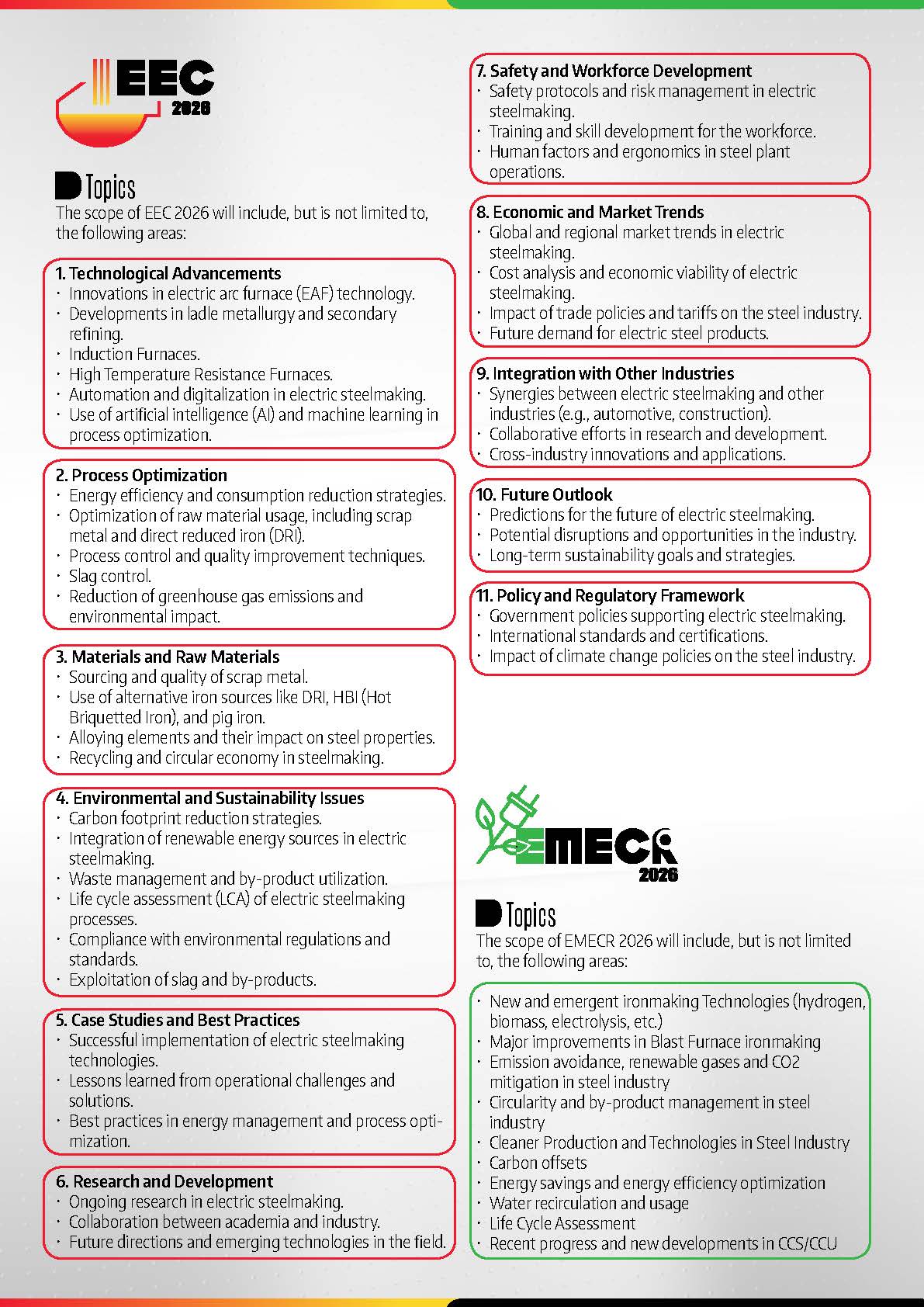

EEC 1 - Technological Advancements

-

EEC 1.A Innovations in electric arc furnace (EAF) technology

-

EEC 1.B Developments in ladle metallurgy and secondary refining

-

EEC 1.C Induction Furnaces

-

EEC 1.D High Temperature Resistance Furnaces

-

EEC 1.E Automation and digitalization in electric steelmaking

-

EEC 1.F Use of artificial intelligence (AI) and machine learning in process optimization

-

-

EEC 2 - Process Optimization

-

EEC 2.A Energy efficiency and consumption reduction strategies

-

EEC 2.B Optimization of raw material usage, including scrap metal and direct reduced iron (DRI)

-

EEC 2.C Process control and quality improvement techniques

-

EEC 2.D Slag control

-

EEC 2.E Reduction of greenhouse gas emissions and environmental impact

-

-

EEC 3 - Materials and Raw Materials

-

EEC 3.A Sourcing and quality of scrap metal

-

EEC 3.B Use of alternative iron sources like DRI, HBI (Hot Briquetted Iron), and pig iron

-

EEC 3.C Alloying elements and their impact on steel properties

-

EEC 3.D Recycling and circular economy in steelmaking

-

-

EEC 4 - Environmental and Sustainability Issues

-

EEC 4.A Carbon footprint reduction strategies.

-

EEC 4.B Integration of renewable energy sources in electric steelmaking

-

EEC 4.C Waste management and by-product utilization

-

EEC 4.D Life cycle assessment (LCA) of electric steelmaking processes

-

EEC 4.E Compliance with environmental regulations and standards

-

EEC 4.F Exploitation of slag and by-products

-

-

EEC 5 - Case Studies and Best Practices

-

EEC 5.A Successful implementation of electric steelmaking technologies

-

EEC 5.B Lessons learned from operational challenges and solutions

-

EEC 5.C Best practices in energy management and process optimization

-

-

EEC 6 - Research and Development

-

EEC 6.A Ongoing research in electric steelmaking

-

EEC 6.B Collaboration between academia and industry

-

EEC 6.C Future directions and emerging technologies in the field

-

-

EEC 7 - Safety and Workforce Development

-

EEC 7.A Safety protocols and risk management in electric steelmaking

-

EEC 7.B Training and skill development for the workforce

-

EEC 7.C Human factors and ergonomics in steel plant operations

-

-

EEC 8 - Economic and Market Trends

-

EEC 8.A Global and regional market trends in electric steelmaking

-

EEC 8.B Cost analysis and economic viability of electric steelmaking

-

EEC 8.C Impact of trade policies and tariffs on the steel industry

-

EEC 8.D Future demand for electric steel products

-

-

EEC 9 - Integration with Other Industries

-

EEC 9.A Synergies between electric steelmaking and other industries (e.g., automotive, construction)

-

EEC 9.B Collaborative efforts in research and development

-

EEC 9.C Cross-industry innovations and applications

-

-

EEC 10 - Future Outlook

-

EEC 10.A Predictions for the future of electric steelmaking

-

EEC 10.B Potential disruptions and opportunities in the industry

-

EEC 10.C Long-term sustainability goals and strategies

-

-

EEC 11 - Policy and Regulatory Framework

-

EEC 11.A Government policies supporting electric steelmaking

-

EEC 11.B International standards and certifications

-

EEC 11.C Impact of climate change policies on the steel industry

-

-

EMECR

-

EMECR 1. New and emergent ironmaking Technologies (hydrogen, biomass, electrolysis, etc.)

-

EMECR 2. Major improvements in Blast Furnace ironmaking

-

EMECR 3. Emission avoidance, renewable gases and CO2 mitigation in steel industry

-

EMECR 4. Circularity and by-product management in steel industry

-

EMECR 5. Cleaner Production and Technologies in Steel Industry

-

EMECR 6. Carbon offsets

-

EMECR 7. Energy savings and energy efficiency optimization

-

EMECR 8. Water recirculation and usage

-

EMECR 9. Life Cycle Assessment

-

EMECR 10. Recent progress and new developments in CCS/CCU

-

Choose timezone

Your profile timezone: